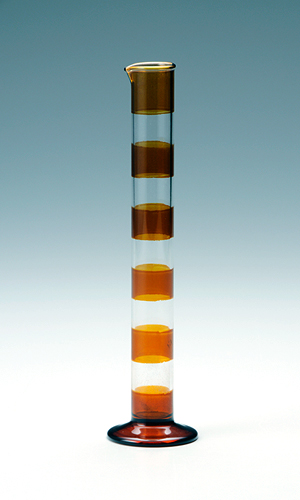

Organic EL Cap Glass

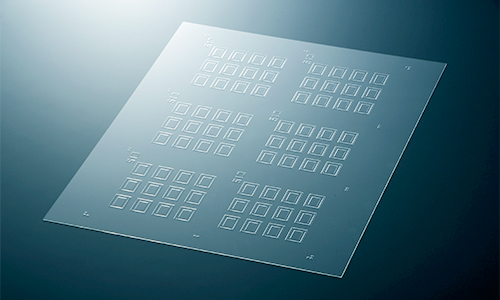

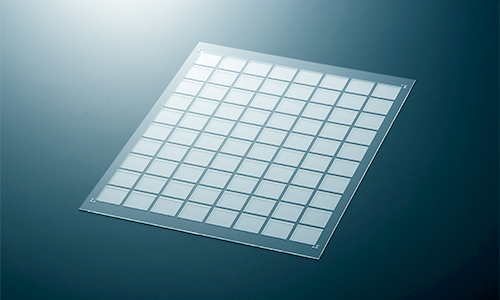

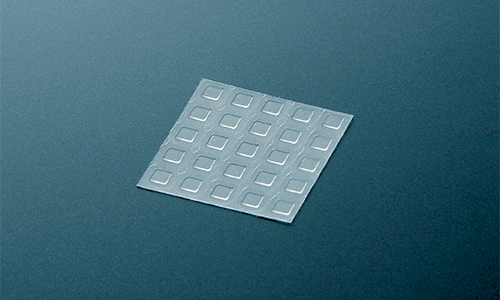

We process glass for sealing the back surfaces of organic electroluminescence (EL) elements to protect them. We also process patterned etching (spot facing) onto glass sheets.

- Delivery formats

- We can provide both (1) large sheets for dividing into multiple pieces and (2) cut products for individual use.

- Glass sheet thickness

- No specific restrictions, but we have processed sheets of 0.3 mm and greater thickness.

- Etching depth

- 50 to 700 μm (in-house results)

- Depth precision

- ±50μm

- Etching methods

- (1) Etching processing, (2) Sand blasting + etching processing

- Surfacing processes

- Glass surfaces can be processed according to customer requests, such as: (1) transparent finish, (2) roughened finish, (3) frosted finish, and (4) with holes added.

We can handle small-lot manufacturing orders. We also accept requests for prototyping.